Cold Work O1 Tool Steel | 1.2580 | SKS3 | 9CrWMn | 2140 | 95MnWCr1

ASISI Cold works O1 tool steel China supplier and Factory for more than 17 years. We Provide the SAE / AISI / ASTM A681 cold work O1 tool steels alloy material in dependable quality and for reasonable price for sale and supply. We focus on Tool Steel material. And deep know the chemical composition and properties of Oil O1 tool steel. Contact us for any O1 tool steel materials inquiry and purchase demands.

ASTM O1 steel is a high carbon(0.9% C), high Manganese Cold work tool steel (1.2% Mn), and with nice wear resisting properties, By the Oil quenching heat treatment can reached to 62 HRc. Oil steel O1 have Higher manganese content and chromium, tungsten content, That can increase the hardening capacity, so that steel does not require vigorous water-cooled quenching. Quenched by oil, but the hardness of up to 62HRC tool. O1 is Very easy to heat treatment. O1 steel has better machinability and wear resistance, heat treatment, stable performance, small size deformation, but toughness and corrosion resistance is weak. O1 steel is the oil quenching tool steel. But somebody call it 01 steel.

. Cold work o1 tool steel hardens in oil with a low order of movement and offers a measure of corrosion resistance while polished. O1’s mechanical properties is very sensitive to heat treatment. SAE SPECIAL STEEL provided in diameter round bar, flat bar, and square block, ground flat stock ,drill rod and 4140 alloy worm screw.

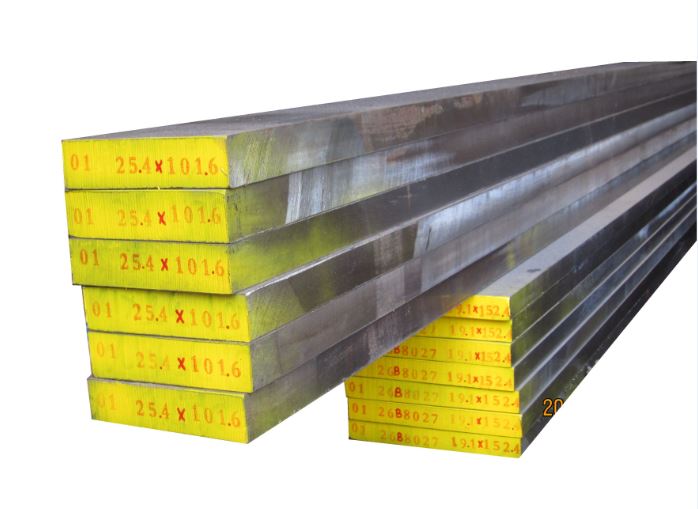

- Supply Range of Cold work O1 Tool Steel (UNS T31501)

ASTM O1 Steel Round Bar: diameter 4 to 350mm x Length 4000mm max.

AISI O1 Tool Steel Plate: thickness 2 to 300mm x width 200 to 800mm x Length 2000 to 4000 mm

Oil O1 Steel Block(Slab): 200mm x 500-800mm

Surface treatment for o1 oil steel: Black, Coarse grinding, finish machining, peeled, Turned machined, Milled or according custom demand.

- Reference standard of O1 Steel Equivalent Specifications

| Country | America | German | Japan | China |

| Standard | ASTM A681 | DIN EN ISO 4957 | JIS G4404 | GB/T 1299 |

| Grades | O1 | 1.2510 /100MnCrW4 | SKS3 | 9CrWMn |

- AISI O1 Tool Steel Chemical Compositioncontrast with equivalent metal material

| ASTM A681 / SAE J437 | C | Si | Mn | P | S | Cr | V | W | ||||||

| O1 | ||||||||||||||

| DIN ISO 4957 | C | Si | Mn | P | S | Cr | V | W | ||||||

| 1.2510/100MnCrW4 | ||||||||||||||

| JIS G4404 | C | Si | Mn | P | S | Cr | V | W | ||||||

| SKS3 | ||||||||||||||

| GB/T 1299-2000 | C | Si | Mn | P | S | Cr | V | W | ||||||

| 9CrWMn | ||||||||||||||

- AISI Grade ASTM O1 Steel Mechanical Properties

| Mechanical Properties | Metric |

| Hardness, Brinell (At Annealing delivery condition) | 190 HB |

| Hardness, Rockwell C (Oil Quenching Hardened delivery) | 62 HRc |

| Elastic modulus (62 HRc) | 193 GPa |

| Elastic modulus (at 399°C, 62 HRc ) | 172 GPa |

| Poisson’s ratio | 0.27-0.30 |

| Compressive yield strength (0.2%, @ 62 HRc) | 2200 MPa |

Thermal Properties

| Properties | Conditions | ||

| T (°C) | Treatment | ||

| Thermal expansion | 10.6 x 10-6/ºC | 20-100 | – |

- AISI/ASTM A681 Steel Grade O1 Forging

AI-SI O1 steel heat should be slowly and uniformly. Soak through at 980°-1000°F and reheat as often

as necessary, Don’t forged when work-piece temperature below 800°C. After ASTM O1

die steel forging, cool slowly in sand, mica, dry ashes or furnace. Annealing is essential after AISI o1 steel forging.

- Heat Treatment-O1 Tool Steel

Heat treatment refers to the material in the solid state, through the means of heating, insulation and cooling, in order to obtain the desired organization and properties of a metal thermal processing. During the period from the Stone Age to the Bronze Age and the Iron Age, the role of heat treatment gradually became known.

Metal heat treatment process can be broadly divided into overall heat treatment, surface heat treatment and chemical heat treatment three categories.

O1 Steel Heat Treatment normal include Annealing, normalizing, quenching, tempering.

- Annealing

For annealing, first heat o1 tool steels material to 740 to 760°C followed cool slowly in furnace until to 500°C or below. Get annealed hardness about 229 HB.

- Stress Relieving

When desirable to relieve the strains of machining, heat O1 steel slowly to 670-700°C, allow to equalize, and then cool in air (Strain Relieving).

- Hardening

Preheat to 300-500°C by Slowly heat. Then raising to 780-820°C quickly. Hold the work piece at the hardening temperature until it is completely and uniformly heated.

- Quenching

AISI O1 steel tool material is an Oil hardening steel and will develop hardness on cooling in still Oil. To avoid scaling and prevent decarburization of the work piece surface, controlled atmosphere or vacuum furnaces are recommended. If these furnaces are not available, pack hardening, salt baths or wrapping the piece in stainless steel foil will provide some degree of surface protection in the hardening process. Parts should be allowed to cool to 150F, or to where they can be held in the bare hand, and then temper immediately.

- Tempering

The tempering temperature on Metal material O1 steel may be varied according to the desired hardness. Temper between 100 to 350°C. Soak still thoroughly. by 25mm thickness per hour least.

- Applicationof Metal O1 Tool Steel Material

USA O1 oil quenching tool steels are used for long run tooling applications, where wear resistance is important, such as blanking or forming dies and thread rolling dies.

Typical applications as below:

o1 steel can apply to Punching die, molding die, stamping die, blades, heading tools, long punch, forming roller, grinding roll, master the tools, ball, punch, perplexing extrusion die, drawing die, compound die, thread rolling die, Shear Blades, Burnishing Tools, Knurls and wear parts list.

We usually hold Oil o1 steel on sale activities, and if you would have our price on regular schedule. Contact us and sign in our newsletter to have O1 tool steel materials price list and commercial quote today.

Contact US: Add: North Industrial Zone,DongGuan, Guang Dong Province. P.R. China Tel: +86-13414322915 Whatsapp/wechat: +86-13414322915 Email: info@saesteel.com